Traceability with Scalable Serial-Number Scanning

Dec 10, 2025

Full serial-number scanning creates reliable module traceability at scale and simplifies future warranty handling.

PV Serial Number Collection

Use Case:

Ensuring Full PV Module Traceability with Scalable Serial-Number Scanning

About the Client:

TQES manages and services photovoltaic assets and is responsible for accurate documentation, long-term performance tracking, and warranty management. Their operations require reliable identification of every module across their sites.

What Problem We Are Helping the Client Overcome:

Tracking serial numbers across large PV sites is time-consuming, error-prone, and nearly impossible to scale using traditional manual methods. Incomplete or inconsistent documentation creates problems later when handling warranty cases, identifying batch issues, or performing audits. The client needed a precise, future-proof way to capture every module’s serial number.

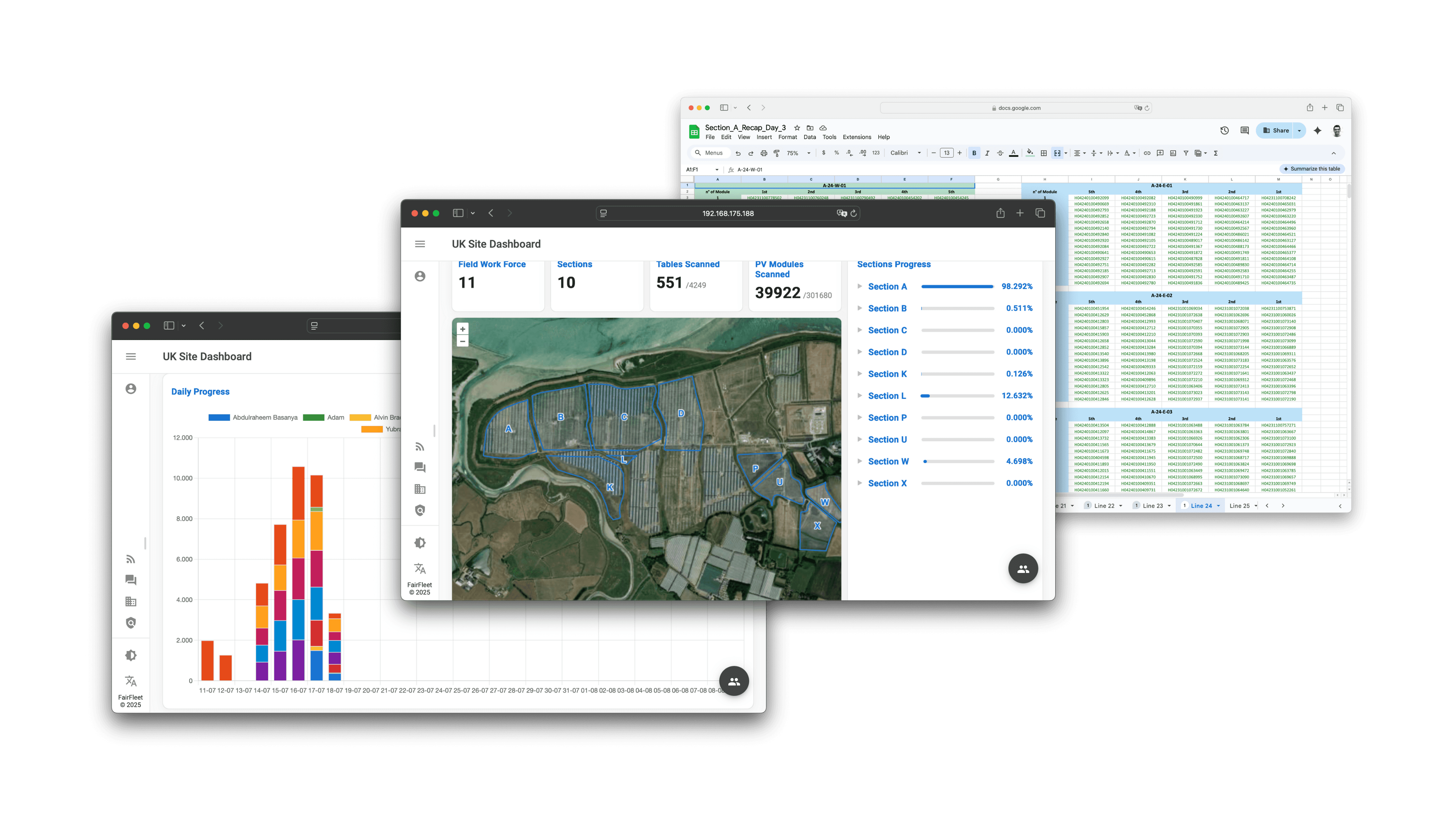

What FairFleet’s Solution Is:

FairFleet supports clients with a serial-number scanning workflow (either drone-based or manual) depending on site conditions and budget. Each module’s serial number is captured, processed, and linked to its exact position on the site, creating a reliable digital record. The data is stored centrally, forming the foundation for long-term traceability, auditing, and warranty handling.

Benefit for the Client:

Serial-number scanning with FairFleet offers the only scalable and cost-effective alternative to traditional manual collection, significantly reducing errors and inconsistencies. For this project, the complete site was scanned manually, as it was the most cost-efficient option while still ensuring full accuracy. With more than 500,000 modules documented, the client now has a precise and dependable dataset for future warranty claims and long-term asset management.